saving energy

Upgraded fluid and lower viscosity grade with DYNAVIS

Cost pressure is a variable in every industry, especially plastics manufacturing. Companies that use injection molding machines are in constant competition for low unit operating costs. Many steps have already been taken in terms of design and in general, newer machines have already been pushed a long way with regard to energy-saving measures.

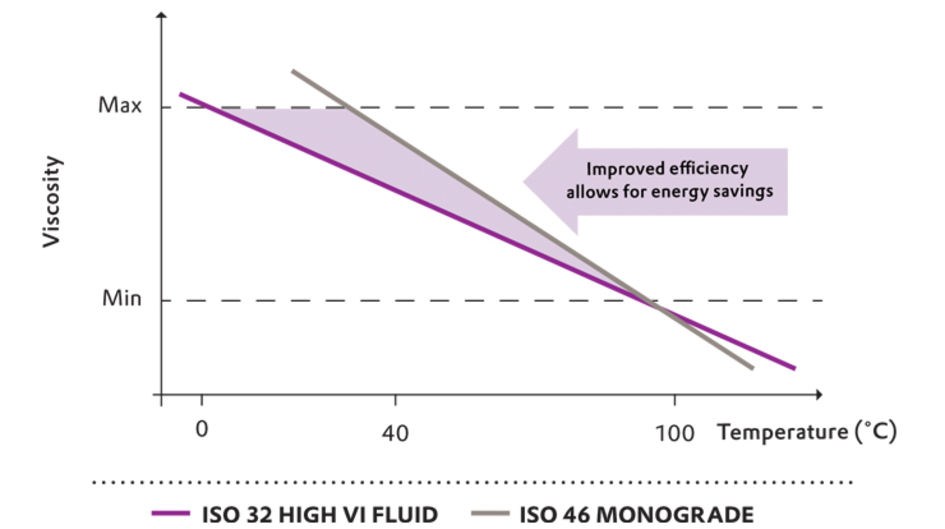

One simple and clever step that can be taken is to change the hydraulic fluid from a standard ISO 46 viscosity grade, to an ISO 32 formulated with DYNAVIS®.

DYNAVIS® technology provides proven and substantial energy savings in a wide range of injection molding machines. It also supports long drain intervals and more machine uptime.

INJECTION MOLDING MACHING SAVINGS

Severals tests run on various injection molding machines confirmed energy savings between 2 to 10% can be achieved depending on setups and machines.

|

Manufacturer |

Energy Savings* |

|

Husky XL 300 |

4.2% |

|

Krauss Maffei KM 80 CX SP 380 |

2-5% |

|

Engle Victory 330/120 |

6.2% |

|

Boy 35 E |

7-10% |

*Savings with ISO VG 32 DYNAVIS® formulated fluid versus incumbent ISO VG 46 monograde.

REDUCE Energy costs - just a click away!

Use DYNAVIS® injection molding calculator to visualize the benefits of efficiency increase such as quick return on initial investment and energy savings that can be expected when switching from the incumbent oil to fluids formulated with DYNAVIS® technology.